Harden Machinery

Solid shredders and sorting solutions

Innovative shredders with a focus on reliability and high capacity.

About Harden

Since 2010, Harden Machinery Ltd. has established itself as a leading manufacturer of industrial grinders, sorters and complete processing lines for handling various types of solid waste. With over 14 years of experience and a dedicated R&D team, Harden delivers reliable solutions to the waste industry globally.

In 2024, Steco became a supplier of Harden's robust grinders and sorting solutions to the Nordic market. We offer their complete product range with special focus on the heavy-duty grinders designed for demanding applications.

Harden's headquarters are located in Zhongshan, Guangdong province, easily accessible from Hong Kong and Guangzhou airports. The region is China's industrial powerhouse and known for advanced manufacturing technology and innovation in environmental technology.

With Harden, you get robust, high-quality equipment at an attractive price!

Shredders

Harden supplies a wide range of one-, two- and four-shaft shredders.

SG3000MP

Single-stage shredder

Efficient single-shaft shredder with indexable cutters and 2x200 kW motor that handles all types of waste - from household waste to tires and industrial waste. The replaceable screen ensures a uniform fraction of 40-130 mm with high capacity and minimal maintenance time.

.jpg?width=2000&height=1500&name=SG3000MP%20(2).jpg)

TPH series

Pre-shredder with hydraulic drive

Hydraulically driven primary shredder designed for volume reduction of bulky waste and pre-treatment of solid waste. With engine power ranging from 132-400 kW and a capacity of 15-80 tons/hour, this robust machine handles complex mixed waste such as untreated household waste, demolition waste and industrial waste. It delivers a uniform fraction of 80-300 mm that is optimal for further sorting.

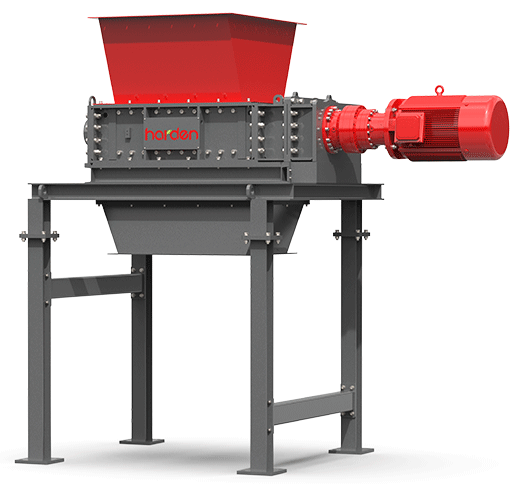

SG series

Single-shaft shredder

Single-shaft shredder with dual motor from 132x2 to 250x2 kW and capacity of 6-20 tons/hour. Specially developed for textiles, leather, plastic film and lightweight materials with patented close-mounted knife design. Delivers consistent 30-100 mm fraction controlled by interchangeable hexagonal screens.

.jpg?width=2000&height=1500&name=SG3000RF%20%20(3).jpg)

SL series

Single-shaft shredder

Single-shaft shredder specially developed for the waste industry, with motor power from 90-160 kW and capacity of 3-5 tons/hour. Delivers a uniform fraction of 40-130 mm and efficiently handles hard plastics, plastic film, polyester textiles and big bags.

.jpg?width=2000&height=1500&name=SL2500%20(8).jpg)

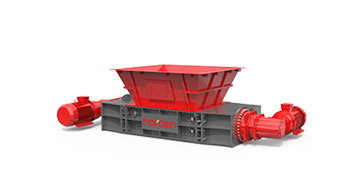

TD series

Two-shaft shredder

Two-shaft shredder with dual motors from 45x2 to 132x2 kW and capacity of 3-30 tons/hour. Two independent shafts with blades create powerful cutting force for coarse crushing of complex materials such as textiles, household waste, tires and bulky waste. Delivers 50-120 mm fraction with automatic overload protection and reverse.

TS series

Two-shaft shredder - medium duty

Compact two-shaft shredder with single motor from 45-75 kW and capacity of 1-10 tons/hour. Designed for lighter materials such as wood, paper, cardboard and confidential destruction. Two shafts are driven by a single motor for efficient cutting power with a 50 mm fraction. Automatic lubrication and dust protection ensure operation with dusty and damp materials.

Screening solutions

In addition to shredders, Harden supplies several types of screens and separators.

Flip-Flow screen

Elastic screen

Advanced screening where elastic screen cloth is stretched and relaxed in rapid succession to create extreme acceleration that prevents clogging. With a 22 kW motor and a capacity of 20-25 m³/hour, it's perfect for wet and sticky materials that conventional screens can't handle. Screening area of 1600x5200 mm with self-cleaning effect. Modular design allows quick replacement of components.

Combi-screen

Three-fraction screen

Innovative screen that combines flip-flow and traditional vibration screening in one machine. With a 45 kW motor and a capacity of 60-80 m³/hour, two screening effects are achieved simultaneously - upper part with circular vibration for coarse screening, lower part with elastic screen cloth for fine screening of sticky materials. The 1600x6000 mm screening area saves space and reduces the need for additional transportation equipment. Perfect for complex material flows.

Triangle Roller Screen

Innovative with patented technology

Innovative screen with rotating triangle rollers that create wave motion for efficient screening. With a 4-5.5 kW motor and a capacity of 15-100 tons/hour, perfect for materials with low moisture and viscosity. Screens fractions from 50-150 mm with patented anti-winding technology that prevents clogging. Modular design with adjustable angle adapts to different materials. Compact design with automatic lubrication and low noise level.

Step Screen

Vibratory for course sceening

Vibratory screen with stepped screen deck and 45 kW motor that handles 80-100 m³/hour. Specially designed for coarse screening of large materials with a screening area of 2000x6000 mm.

Disc Screen

Polygonal disc screening

Screen with rotating polygonal discs and 7.5 kW motor that handles 15-20 tons/hour. Adjustable screen openings from 20-350 mm adapt to different materials. Patented anti-winding design prevents jamming of hard materials and winding problems. Modular design with frequency regulation for optimal capacity.

Areas of application

Harden's solutions cover a wide range of waste types:

- Household waste (MSW)

- Bulky waste and furniture

- Industrial and manufacturing waste

- Tires and rubber waste

- Paper and residual waste from paper mills

- Old landfills

Service and support

Through Steco you get access to:

- Tailor-made solutions adapted to Nordic conditions

- Technical advice and engineering

- Spare parts and service

- Training and operational support

- Parts warehouse in Drammen, Norway

More information?

Use our contact form via the button below to send us an inquiry.

Get in touch with us!